Back to the news list

Back to the news list

Crude oil undergoes an initial processing stage where its components are separated into valuable fractions such as gasoline, diesel, and many other products. This process is carried out in a crucial piece of equipment known as the crude oil distillation tower. To gain a better understanding of its functions and working principles, let’s dive into the details in this article by NSRP.

A distillation tower, also known as a crude oil distillation column, is a piece of equipment used in crude oil distillation units to separate liquid mixtures into distinct fractions based on their boiling points. This process begins by heating the liquid mixture to generate vapor, which is then introduced into the distillation tower. The vapor condenses back into liquid form through cooling, and the liquids are collected on trays positioned at different heights within the tower, depending on the boiling points of the individual components.

The distillation process not only separates the components but also enhances the purity of the distilled products. For this reason, the distillation tower is an essential piece of equipment in many industries, particularly in oil refining, where it helps break crude oil down into valuable products such as gasoline, diesel, and liquefied petroleum gas (LPG).

The crude oil distillation tower is a crucial device in oil refining and petrochemical plants.

Distillation towers are widely used in the petrochemical, chemical, and pharmaceutical industries for purifying and separating various chemicals. The design and operation of a distillation tower can vary significantly depending on the type of liquid mixture being distilled and the desired final products. Distillation towers can be optimized for maximum efficiency in separating components based on factors such as temperature, pressure, and the characteristics of the substances being processed.

Key functions of the distillation tower:

Distillation towers are used to purify products by separating unwanted substances based on their boiling points. Lighter components are collected at the top of the tower in a purer state, while heavier components are gathered in the lower sections, ensuring that the final products meet high-quality standards.

Additionally, distillation towers are used to concentrate substances by removing less volatile components. This process is commonly applied in the production of distilled spirits and vegetable oils, where impurities need to be eliminated, or the concentration of valuable compounds needs to be increased.

In the oil refining industry, distillation towers play a critical role in separating crude oil into various fractions such as gasoline, kerosene, and diesel. This separation process allows for the extraction of valuable products from crude oil, serving both industrial and consumer needs. It is an indispensable step in energy production.

As mentioned earlier, distillation towers have different designs and components depending on their intended use and final product requirements. However, a typical distillation tower includes the following main components:

The reboiler, also known as a heat exchanger, is located at the base of the tower (reboiler) or in a furnace used to heat the feedstock. Its function is to provide the necessary heat to partially vaporize the liquid feed entering the tower. This liquid mixture is fed into the center of the tower, flows downward into the separation section, and then into the reboiler, where it is heated to generate vapor. The vapor then rises through the tower via convection, continuing the separation process.

Depending on the application, a distillation tower may or may not have a reboiler. However, the fundamental principle remains the same: heat must be applied to the feedstock to generate liquid and vapor for the distillation process.

The column body is where the liquid-vapor phase separation occurs. It contains trays designed to create contact surfaces for vapor and liquid, facilitating efficient heat and mass exchange. This interaction enables the separation of crude oil fractions based on their boiling points. Vapors rise from the bottom of the tower, while liquids flow downward, resulting in effective fractionation.

Located at the top of the tower, the condenser functions to cool and condense the separated vapor back into liquid form. Once condensed, the liquid is collected before entering the reflux drum. This process helps recover separated products and improves distillation efficiency.

The reflux drum collects the condensed vapor in liquid form from the top of the tower. The liquid collected in the reflux drum is then divided into two streams:

How crude oil is fractionally distilled in the distillation tower (Image Source: Bismarck State College National Energy Center of Excellence)

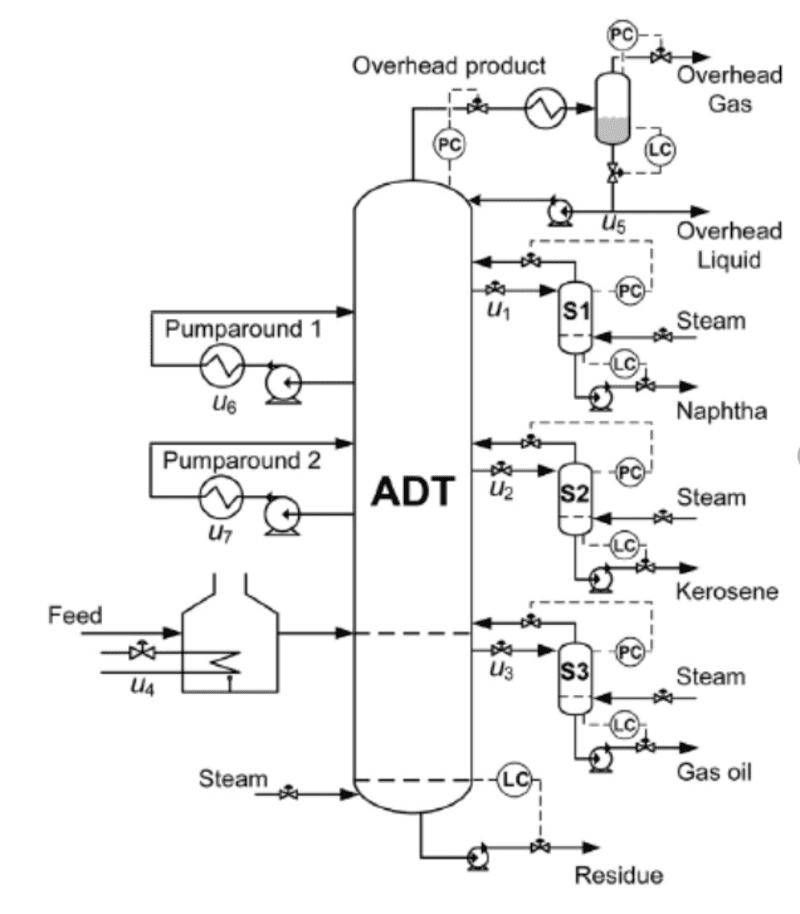

Additionally, heat exchangers (pumparound systems) are integrated around the crude oil distillation tower to optimize heat recovery and enhance separation efficiency and product purity.

The crude oil distillation tower is an indispensable piece of equipment in oil refining and processing, facilitating the separation of crude oil components to produce valuable products that serve industrial and consumer needs.

Không thể sao chép