Nghi Son Refinery & Petrochemical Complex is one of the national key projects which apply the world’s most advanced technologies with a total investment of USD9 bln. The owner of the complex is Nghi Son Refinery & Petrochemical LLC., which is shared by four big petroleum corporations from Japan, Kuwait and Vietnam. The Project is planned to last for 70 years with the aim to devote to the national energy security and contribute to the economical development of Vietnam. The Project’s Ground Breaking ceremony was held on October 23rd 2013. On February 28th 2018 after 4 years of construction, Nghi Son Refinery & Petrochemical LLC. organized the Ready For Start Up (RFSU) signing ceremony. Following the RFSU, the Refinery stepped into commissioning phase. In parallel with commissioning of Process Units, NSRP also put the environmental protection facilities into commissioning following the commitments made at the approved EIA. With its sustainable performance in commissioning which satisfies environmental standards, on August 5th 2019 the Project has obtained the “Certificate For Completion of Environmental Protection Facilities of Nghi Son Refinery & Petrochemical Complex Project” which was granted by Ministry of Natural Resources and Environment.

Committing to the ultimate principle “No trade-off between environmental protection and economic growth”, NSRP always puts the environmental protection first and has invested a total of USD300 mln (Approximately VND7,000 bln) solely for the construction and installation of environmental protection facilities which apply the most advanced technologies from developed countries such as Japan, Korea, and EU to minimize the impacts on air, water and soil environment. The discharging sources are treated to satisfy the stringent environmental standards of IFC/World Bank as well as standards/regulations of Vietnam. Additionally, the design of the refinery has already integrated technologies to optimize the use of energy as well as to recover the heat from products.

To minimize air pollution during its operation, NSRP has applied various advanced pollution abatement technologies to satisfy the air emission standards such as: designing proper height of stacks, using Low-NOx burners for heaters, De-NOx by SCR, De-dust by ESP and De-SOx by seawater for boiler emission; De-NOx by SCR, De-SOx and De-dust at CO incinerator of RFCC Unit, tail gas treatment system at SRU to recover maximum liquid Sulphur, VRU at truck loading and Jetty.

SOx, NOx, Dust emissions emitted to environment are monitored by online emission monitoring systems installed on 20 stacks following requirements at EIA approving Decision. Furthermore, NSRP has also installed 03 Ambient Air Quality Monitoring Systems (AAQMS) at different locations inside the Refinery.

The Effluent Treatment Plant (ETP) of NSRP was designed with 2 parallel treatment chains with the capacity of each chain being 350m3/hour. The sources of effluent coming from process and domestic units are collected and treated in the following processes: API Oil separator—API secondary oil separator, FFU and DAF, Bio treatment package, tertiary oxidation package (ozone), tertiary physiochemical treatment package (absorbed by activated carbon). The entire ETP is operated automatically and semi-automatically through another automatic measuring system. Besides, the ETP is also equipped with a spent caustic treatment package and catalyst oxidation system to treat vent gases from the other packages. Treated wastewater is monitored by an online monitoring system for flow rate, temperature, pH, COD, TSS, Total Nitrogen, total P, Phenol and total oil and grease which has been installed at treated transfer sump.

Wastewater from Demineralized Unit, from FGD and cooling seawater are properly treated and monitored by online monitoring systems for typical parameters prior to discharging into the environment complying with applicable regulations.

Additionally, NSRP engages with an authorized monitoring center to monitor the quality of treated wastewater periodically. The monitoring results indicate that all the pollution contents are below the allowable limits of QCVN 40: 2011/ BTNMT.

Follow the requirements at Circular 36/2015/TT-BTNMT – Hazardous waste management, NSRP has registered the Hazardous Book Owner No. 38000296.T to Thanh Hoa Department of Natural Resources & Environment. NSRP installed 18 temporary HW storages at various locations within the process area and 1 centralized HW storage with an area of 700m2 to store the wastes prior transferring to contractor. NSRP also signed a Contract with Nghi Son Environment Joint Stock Company to collect, transport and treat hazardous and non-hazardous wastes generated during its operation.

NSRP also built a fluidized bed incinerator which applies advanced Japan’s technology which is applied in Vietnam for the first time to treat sludge waste generated from ETP and waste oil from PPU. Flue gas treatment system of the incinerator including quencher to control the formulation of Dioxide, bag filter to remove dust and acid absorber by caustic. Flue gas quality is monitored by online analyzers for total dust, SOx and NOx to assure the concentrations of pollutant satisfy QCVN 30:2012/BTNMT prior discharging into the environment.

To minimize noise, units and equipment generating high levels of noise such as Boilers, Turbine Generators etc., are located at the center of the Refinery and silencers are used to lower the noise. Additionally, operators who work in workplace environment with high noise levels (>85 dB(A)) are equipped with proper PPEs.

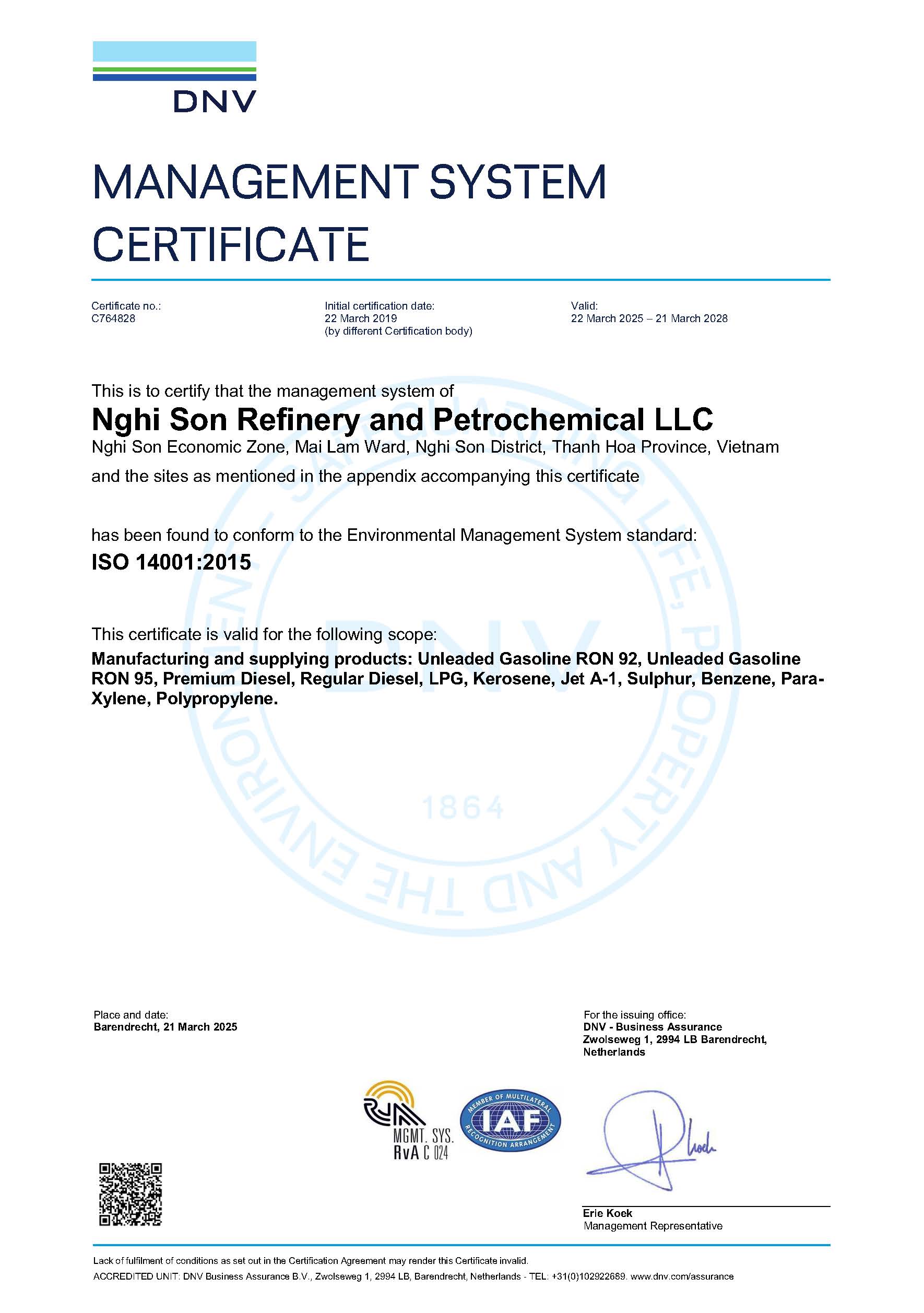

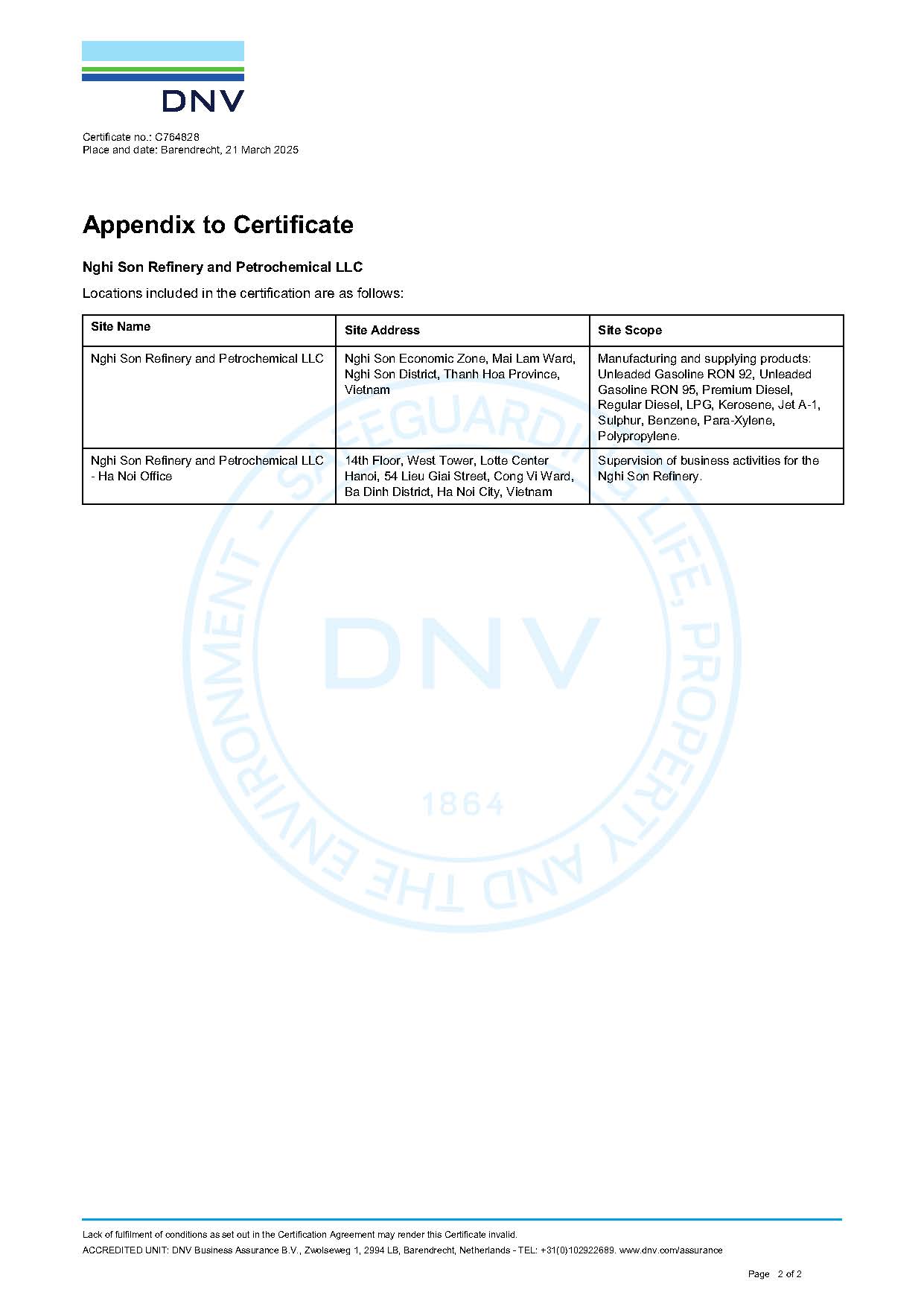

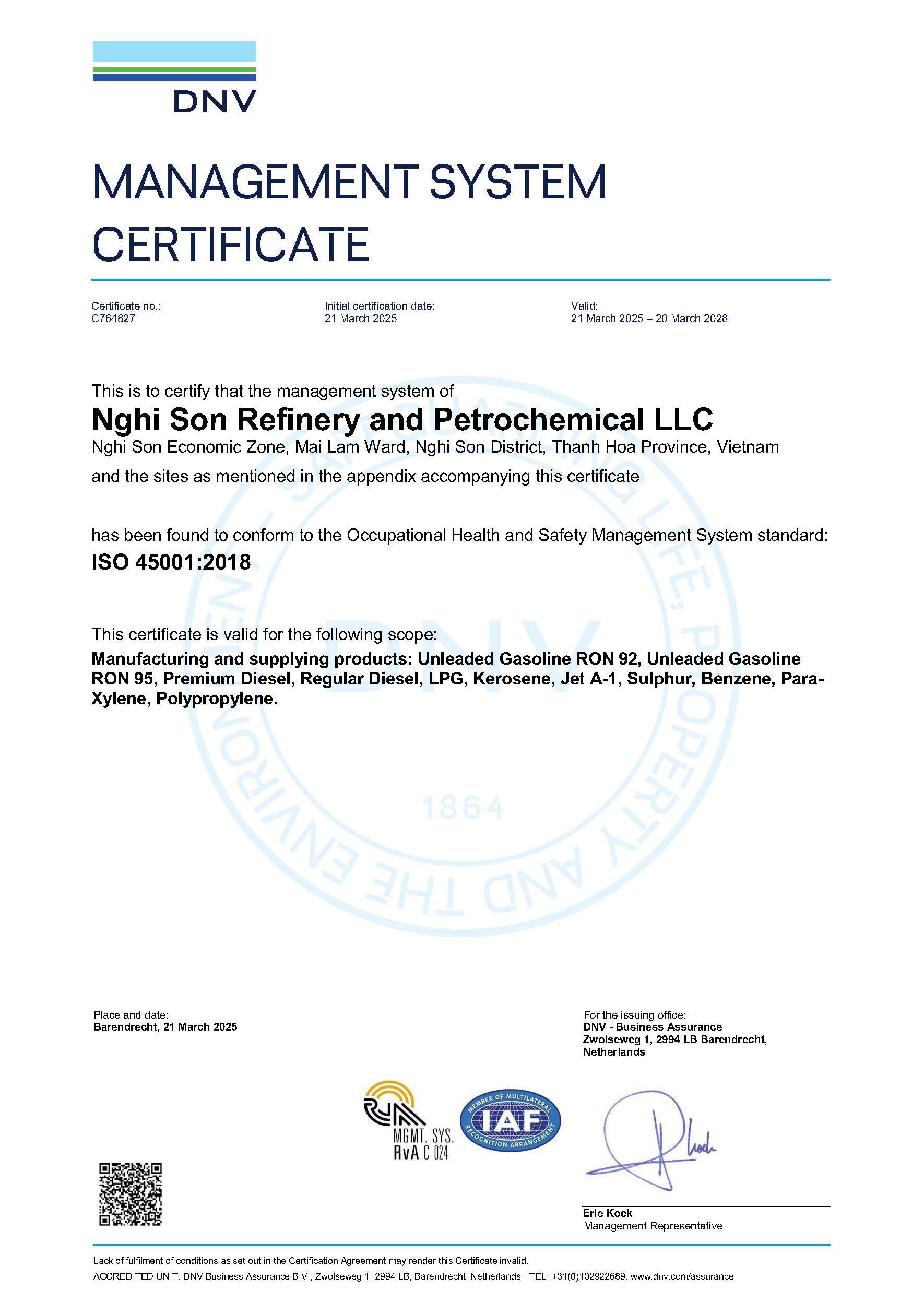

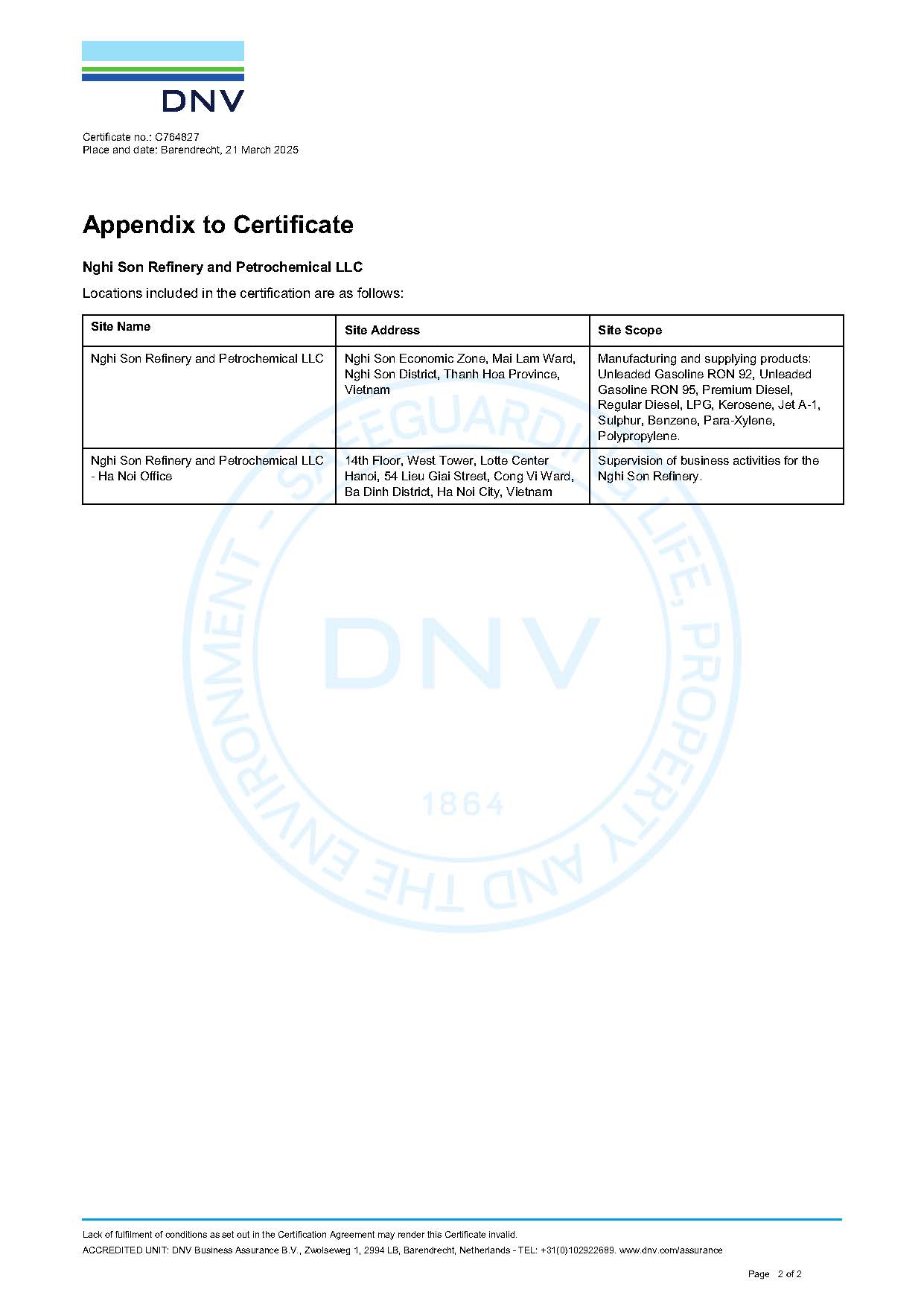

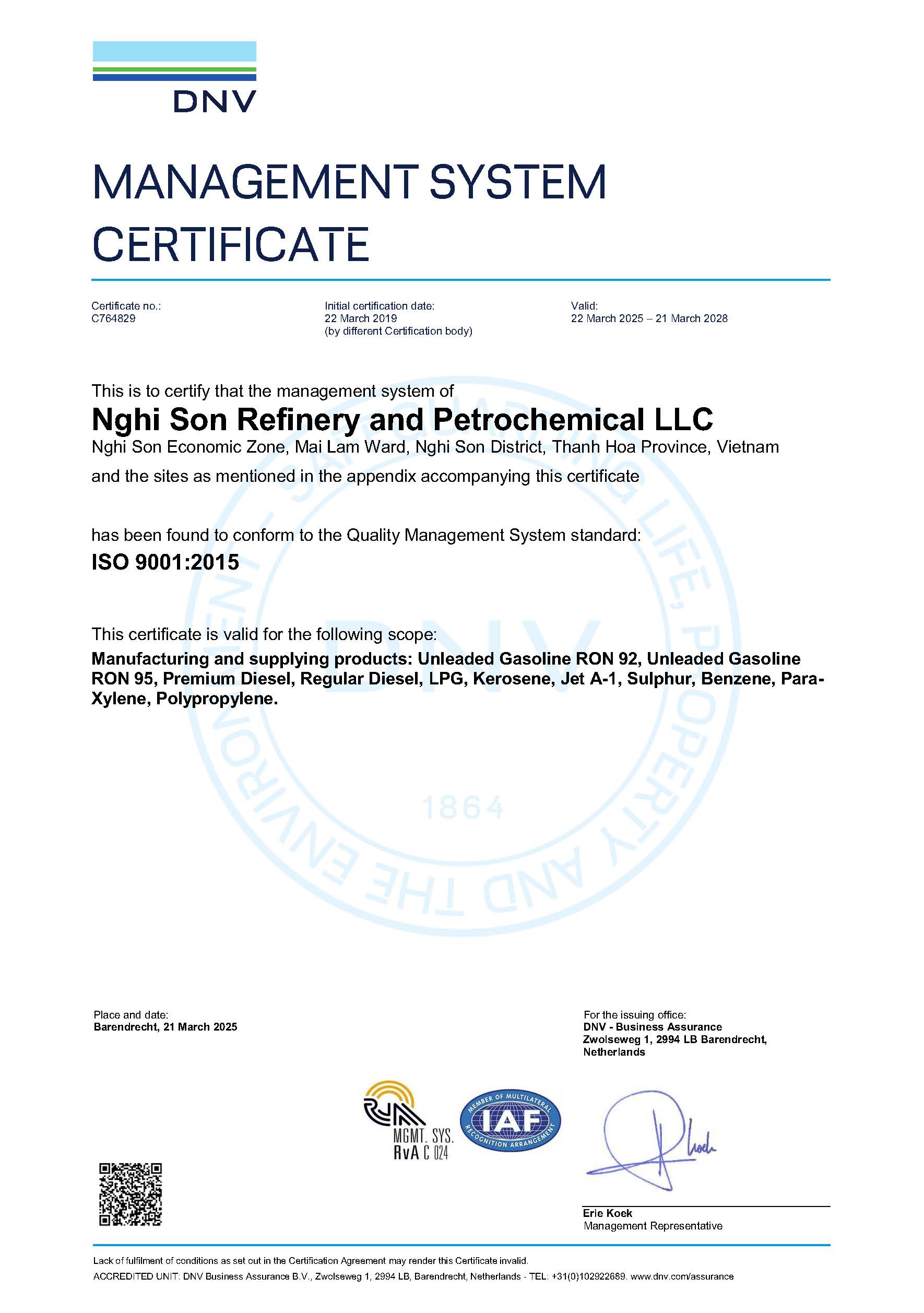

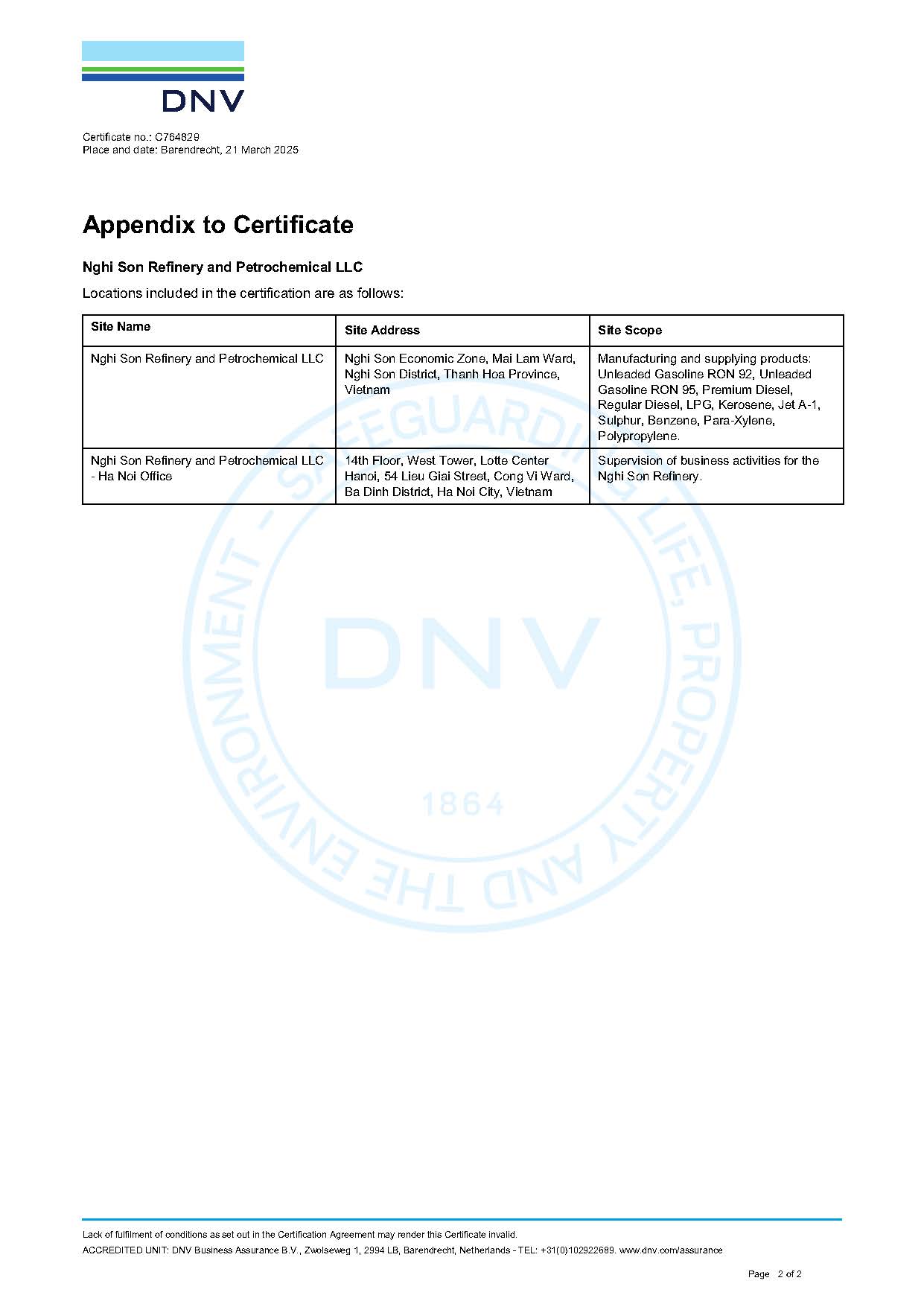

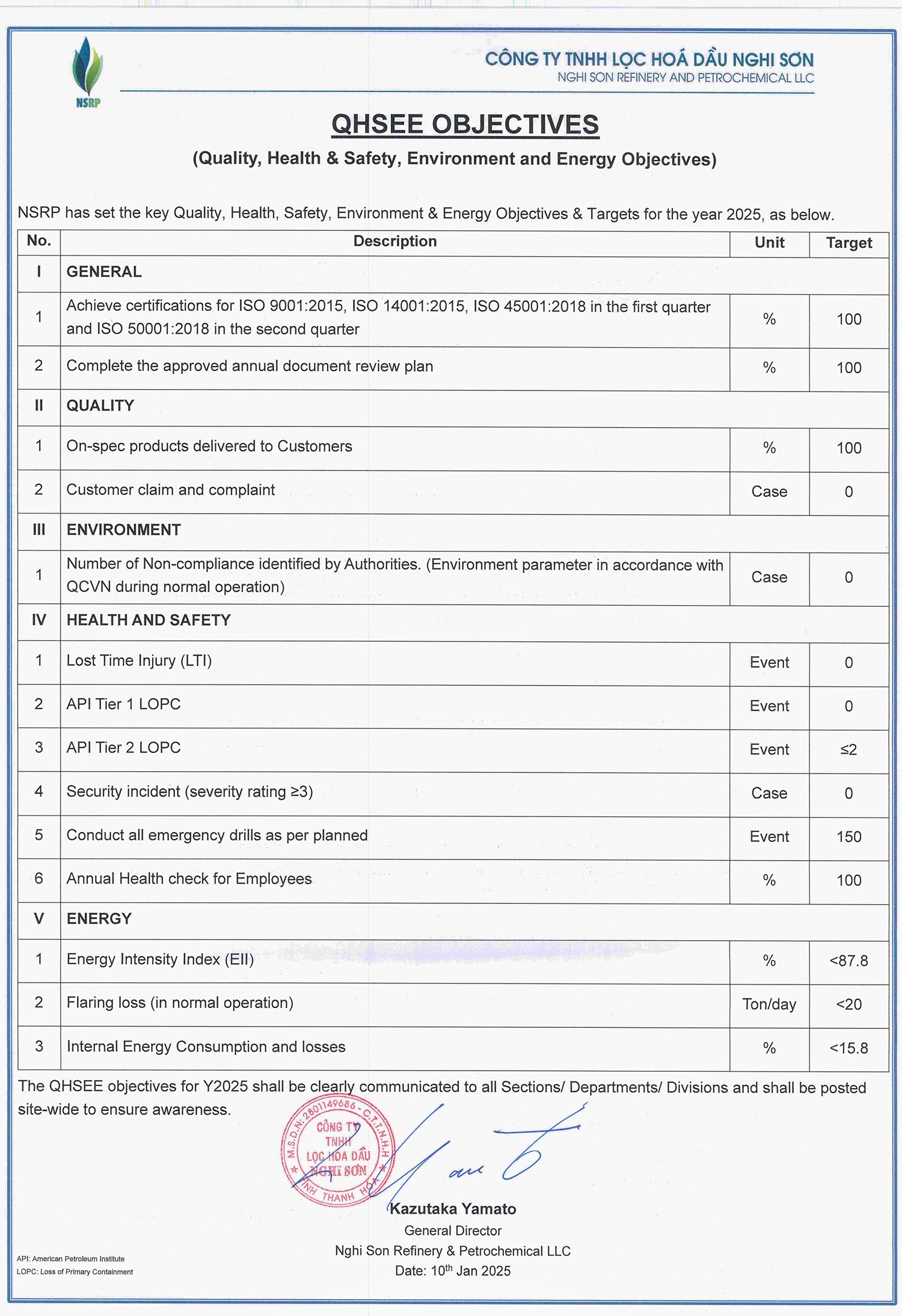

NSRP has successfully developed and applied the Integrated Management System (IMS) following ISO 14001:2015 for environmental management system and ISO 9001:2015 for quality management system which have been assessed and certified as complying with ISO 14001 and ISO 9000 by DNV-GL on 22/3/2019.

The Company also obtained Certificates and Licenses of environmental, health & safety and firefighting and fire protection following Vietnamese regulations such as Permit for discharging wastewater into water source, Permit for seawater exploitation and using, registration of hazardous waste owner book, approval of Oil spill contingency plan, approval of chemical incident prevention and response plan, and certificate for appraising and approving firefighting and fire protection plan.

Following the right direction, NSRP is thriving to become one of the most admired refineries in Asia, not only in terms of product quality, economic efficiency, but also in safety and environmental protection.

Không thể sao chép