Back to the news list

Back to the news list

Oil extraction is a sophisticated process that requires the integration of advanced technologies and a series of precise technical steps. Crude oil is a vital resource that fuels various industries, including energy, petrochemicals, and plastic production. However, extracting oil is not simply about drilling and retrieving it from underground. The process involves multiple critical stages, each demanding specialized techniques and technologies. In this article, NSRP takes a closer look at oil extraction process.

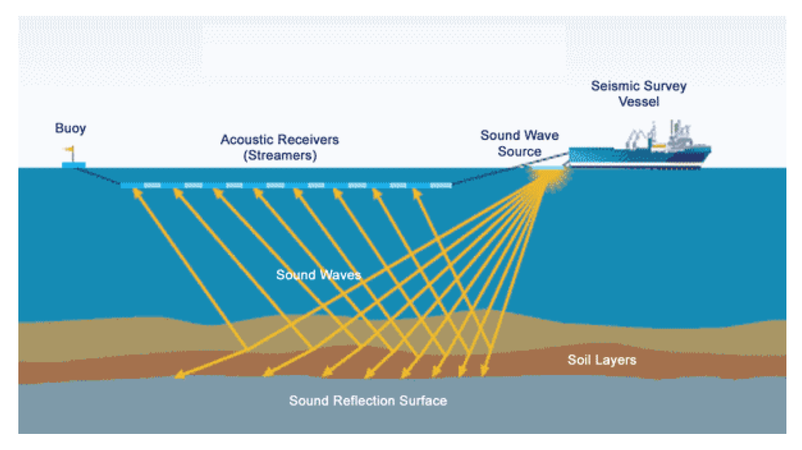

The first step in oil extraction is the exploration and identification of potential oil reserves. Seismic technology is a traditional method used by geologists to detect underground oil reservoirs. This process involves creating controlled underground explosions and analyzing the returning seismic waves to map the geological structure and density of rock layers, helping experts locate potential oil-bearing areas.

Today, in addition to seismic surveys, modern techniques such as magnetic, gravity, and geochemical surveys are also employed. Magnetic methods detect slight variations in the Earth’s magnetic field, which can indicate subsurface oil flows. Additionally, ultra-sensitive electronic probes are used to detect hydrocarbon traces, the primary component of crude oil.

These exploration surveys often take years and require detailed analysis of the geological structure. Once a potential oil field is identified, further studies are conducted to assess its size, extraction potential, and environmental, social, and economic factors.

Exploration and identification of potential oil reserves (Source: AAPG Wiki)

After identifying promising locations, the next step is drilling to access and extract the oil. Drilling is a highly specialized process that requires advanced equipment to penetrate the Earth’s crust and reach the oil-bearing rock layers. Oil wells can extend thousands of meters underground or beneath the seabed in offshore fields.

Depending on the terrain and location of the oil reserves, different drilling methods are used, including onshore and offshore drilling. Offshore drilling platforms can be either fixed or floating, with each type designed to suit specific geographical conditions.

During the drilling process, several challenges may arise, such as pressure fluctuations, extreme temperatures, or water intrusion into the oil reservoir. Engineers must carefully manage these factors to prevent accidents and ensure the safety of operations.

Drilling for Oil

Once drilling is completed, the extraction and recovery phase begins. In many cases, crude oil does not flow naturally to the surface, requiring additional techniques such as pumping, gas injection, or water injection to enhance oil recovery from rock formations.

After being extracted, crude oil must be transported to refineries or distribution centers. This is done through pipelines, oil tankers, or, in some cases, trucks for short distances.

Pipelines are the most efficient and cost-effective method for transporting crude oil, spanning thousands of kilometers to connect remote oil fields with refineries or export ports. When pipelines are not feasible, oil tankers serve as the primary means of transportation, especially for offshore oil fields.

The crude oil tanker from Kuwait to Nghi Son Refinery & Petrochemical

Oil extraction provides significant economic and industrial benefits:

Oil extraction process is a complex sequence of steps, from exploration and drilling to extraction, transportation, and utilization. NSRP hopes that this article provides a comprehensive overview of how crude oil is extracted and brought to market.

Không thể sao chép