Back to the news list

Back to the news list

Residue hydro-de-desulfurization (RHDS) is the one of the most important units in an integrated oil refinery as NSRP. It is designed to process atmospheric residue from the Crude Distillation Unit (CDU) to produce a feedstock suitable for processing in a downstream Residue Fluid Catalytic Cracking (RFCC) – The heart of the Refinery. The RHDS and RFCC will process up to 105,000 barrels/day and 80,000 barrels/day, respectively.

Normally, a RHDS catalyst can operate continuously for 1 year. After this time, the catalyst will be deactivated and needs to be replaced. In order to keep normal operation, RHDS unit has been designed to have 2 identical Modules: Module 1 and Module 2. Due to the life cycle time of the RHDS catalyst, this year, NSRP has planned and decided to replace the afore-mentioned Modules in the second week of April 2020 and June 2020. When one module is shut down, the other one will keep running normally.

However, due to the COVID-19 pandemic, all logistic arrangement and plan had faced with difficulties to mobilize the foreign experts to Vietnam to carry out the catalyst replacement. Fortunately, thanks to the strong support of NSEZ Management Board and leaders of Thanh Hoa Province, on April 19th, NSRP and Ngan Hai Chemical & Technical Services JSC – The main Contractor had successfully brought 104 foreign experts, including 2 experts from South Africa,1 expert from New Zealand and 101 experts of CR Asia Thailand Co., Ltd. from Thai Lan to Vietnam to conduct the job after 14 days of being quarantined and tested negative to SAR-CoV-2.

Experts entered Vietnam via Noi Bai International Airport

All experts and workers must measure body temperature as well as wash their hands, disinfect, and declare medical form before working at NSRP

Finally, the RHDS Catalyst change-out for Module 1 was enabled to start from 1st of May 2020. After being shut down and isolated, the Module 1 was handed over from Operation/Section 2 to Maintenance team and the Contractor to proceed catalyst replacement on May 2th . The catalyst replacement was then successfully completed after 01 month of hard working and effective collaboration among the Operation, Maintenance team and the Contractor. As a result, the Module 1 has operated normally since June 13th.

1.Preparation phase: all activities conducted during this preparation phase lasted for about 2 months, starting from end of March to early May 2020.

1.1. Online safety training courses for the Contractor and experts

Bearing in mind the motto of “Safety First”, all experts from the Contractor were requested to take 10 in-house training courses before working in NSRP in accordance with HSSE procedure requirements. Due to the nCov-19 pandemic, all training courses were conducted online.

1.2. Equipment inspection in Thailand:

Previously, to ensure all equipment meeting all NSRP’s standards and regulations before bringing to Vietnam, in March 2020, NSRP’s Maintenance and HSSE department had sent members to Thailand to inspect all equipment including: Hand tools, Lifting equipment, Hydro-drilling equipment, Electrical Tool, BA and Air Supply for 1 week. There were total 1692 equipment that need to be inspected and transferred from Thailand to Vietnam.

Maintenance and HSSE team went to Thailand to inspect hand tools and mechanical lifting equipment at CR Asia (the Contractor) base

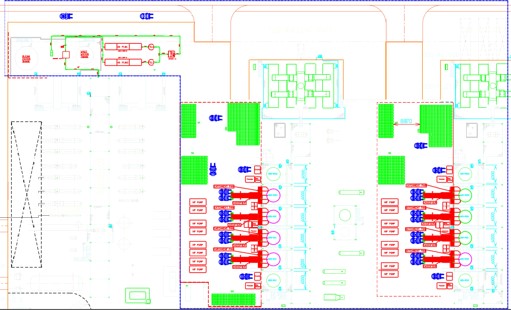

1.3. Equipment lay out setting up

All equipment from the Contractor must be ready to use right after NSRP hands over the RHDS Module 1 for catalyst replacement. Hence, with strong support from Operation/ Section 2 team together with close guidance and supervision of Maintenance team, the Contractor had completed proper arrangement and setting up of equipment in advance to ensure proceeding the job smoothly and effectively.

1.4. New catalyst arrangement and spent catalyst treatment plan

There were total 1275 pallets that need to be transferred to site for loading catalyst for each Module that required around 2200m2. Hence, one of the difficulties that we had to solve was to arrange space to store new catalyst and available space for spent ones since proper placement of catalyst at suitable location would enable the quick access and help reduce transportation time when loading each layer of catalyst.

Equipment layout had been set out in advance

There were total 1275 pallets that need to be transferred to site for loading catalyst for each Module

1.5. Module 1 shutdown while keeping normal operation of Module 2

In order to keep stable and continuous operation activities of the whole Refinery, Section 2 had to shut down Module 1 while keeping Module 2 and other units working in normal operation. This was a critical time that required a huge amount of manpower and focus at high level of all the operators and Managers. However, the Core team had overcome this period with no delay causes by operation reason in the safe manner.

1.6. Running test for water treatment package

Water treatment package is the process to treat the water used for hydro-drilling process then recycle it in a circle. This system consists of many equipment and it needs to be set up and tested before starting the catalyst replacement process.

1.7. Safety review before handing over the reactor system to the Contractor

To ensure safety condition before handing over to the Contractor, NSRP had conducted the Safety Review to reaffirm all items to be in safe place before commencement of catalyst replacement in compliance with the Permit To Work system. Specifically, in the Safety Review meeting, Section 2, the Contractor and HSE experts had discussed and reviewed all supporting document related to PTW/JSA/SWMS to ensure them meeting all safety requirement as per Standard & NSRP policies and procedures.

The contractor conducts a daily START meeting daily at RHDS unit before the work

2. Execution Phase: this phase was completed successfully within 01 month, from May 7th to June 5th that comprised of the following activities:

2.1. Unload the spent catalyst: the Spent catalyst inside the reactor were removed by hydro-drilling and free flowing.

Remove spent catalyst by hydro-drilling

2.2. Load the fresh catalyst:

Experts go inside the reactor

In spite of many external difficulties such as weather conditions (hot temperature and heavy rain), working under harsh condition of confine space (inside the narrow reactor) and complex communication in multiple languages, these afore-mentioned sophisticated works were accomplished successfully thanks to great effort of the Contractor and especially smooth coordination between the Maintenance and Operation – Section 2 team, creating a good base for the 2nd catalyst replacement for RHDS Module 2 which shall take place from June to July 2020.

Once again, CONGRATULATIONS for all the hard works and contribution to the success of the RHDS catalyst replacement!

Operation – Section 2, Maintenance and the Contractor CR Asia Thailand team at site

Không thể sao chép